The smart Trick of Roar Solutions That Nobody is Talking About

The smart Trick of Roar Solutions That Nobody is Talking About

Blog Article

Fascination About Roar Solutions

Table of ContentsRoar Solutions Things To Know Before You BuySome Of Roar SolutionsThe Best Strategy To Use For Roar SolutionsNot known Details About Roar Solutions

The tools register is a detailed database of tools documents that includes a minimum set of fields to recognize each item's location, technological parameters, Ex-spouse category, age, and ecological information. This details is vital for tracking and handling the tools efficiently within harmful areas. On the other hand, for regular or RBI sampling assessments, the grade will be a combination of Comprehensive and Close examinations. The ratio of Comprehensive to Shut examinations will be determined by the Tools Threat, which is examined based on ignition risk (the probability of a source of ignition versus the possibility of a flammable environment )and the hazardous area classification( Zone 0, 1, or 2). This variant will certainly likewise affect the resourcing requirements for job preparation. When Whole lots are defined, you can create tasting plans based upon the sample dimension of each Great deal, which describes the variety of arbitrary equipment products to be inspected. To identify the required sample dimension, two aspects require to be examined: the size of the Whole lot and the category of examination, which shows the level of effort that should be applied( reduced, normal, or boosted )to the examination of the Whole lot. By integrating the classification of assessment with the Great deal dimension, you can then establish the ideal being rejected criteria for a sample, meaning the permitted variety of faulty things located within that example. For more information on this procedure, please describe the Power Institute Standards. The IEC 60079 conventional recommends that the optimum period between assessments should not surpass three years. EEHA inspections will likewise be performed beyond RBI projects as component of scheduled upkeep and tools overhauls or fixings. These evaluations can be credited toward the RBI example sizes within the impacted Lots. EEHA evaluations are carried out to determine mistakes in electric devices. A weighted racking up system is crucial, as a single tool might have multiple mistakes, each with differing levels of ignition threat. If the combined score of both examinations is much less than two times the fault score, the Whole lot is deemed appropriate. If the Whole lot is still thought about inappropriate, it must go through a complete evaluation or justification, which may set off stricter assessment protocols. Accepted Whole lot: The reasons for any kind of faults are determined. If a common failure mode is found, additional equipment might need maintenance. Faults are identified by seriousness( Safety, Honesty, Housekeeping ), making sure that immediate concerns are evaluated and addressed immediately to minimize any influence on safety and security or procedures. The EEHA database ought to track and tape the lifecycle of mistakes together with the corrective actions taken. Carrying out a robust Risk-Based Inspection( RBI )method is crucial for making certain compliance and safety and security in managing Electric Tools in Hazardous Areas( EEHA). Automated Mistake Scoring and Lifecycle Administration: Easily take care of faults and track their lifecycle to improve inspection precision. The intro of this assistance for risk-based evaluation additionally enhances Inspectivity's setting as a best-in-class option for regulative conformity, in addition to for any type of asset-centric inspection usage instance. If you are interested in finding out more, we invite you to request a demo and uncover how our option can transform your EEHA management processes.

With over ten years of mixed Ex-spouse experience (IECEx/ATEX, EEHA), Saipex started to promote the significance of capability of all employees associated with the Hazardous Area area in 2019. In 2021, our collaboration with IndEx and Tech Ability International (TSI) noted a milestone in the Saipex road to continue Ex-spouse improvement.

The Greatest Guide To Roar Solutions

In terms of explosive threat, an unsafe location is a setting in which an eruptive ambience exists (or might be expected to be present) in quantities that call for unique safety measures for the building and construction, installation and usage of tools. In this post we discover the difficulties faced in the office, the danger control procedures, and the required expertises to work securely.

(https://www.metooo.io/u/roarsolutions)

These materials can, in particular conditions, form explosive environments and these can have major and unfortunate consequences. Many of us are acquainted with the fire triangular remove any type of one of the three elements and the fire can not occur, however what does this mean in the context of dangerous locations?

This is then verified through assessment and screening and is protected throughout the life of the installment by using the right upkeep methods, supplemented by routine examination. When all these measures are taken, they ought to additionally be recorded. The confirmation dossier includes info such as the hazardous area category illustration, manufacturers' documents, devices qualification, layout illustrations and calculations, assessment records, and records of a person's expertise and proceeding specialist advancement (CPD), such as via ECA's eCOMS software application.

The Best Strategy To Use For Roar Solutions

It is essential that students understand and have a detailed expertise regarding what precisely constitutes a hazardous location. The pupil should additionally recognize why training is very important before trying to tackle job or specifying tools right into a hazardous area. These locations are also called identified areas and are defined as locations which have a high chance of an explosion because of the possible presence of combustible gases, vapors, dusts and so on.

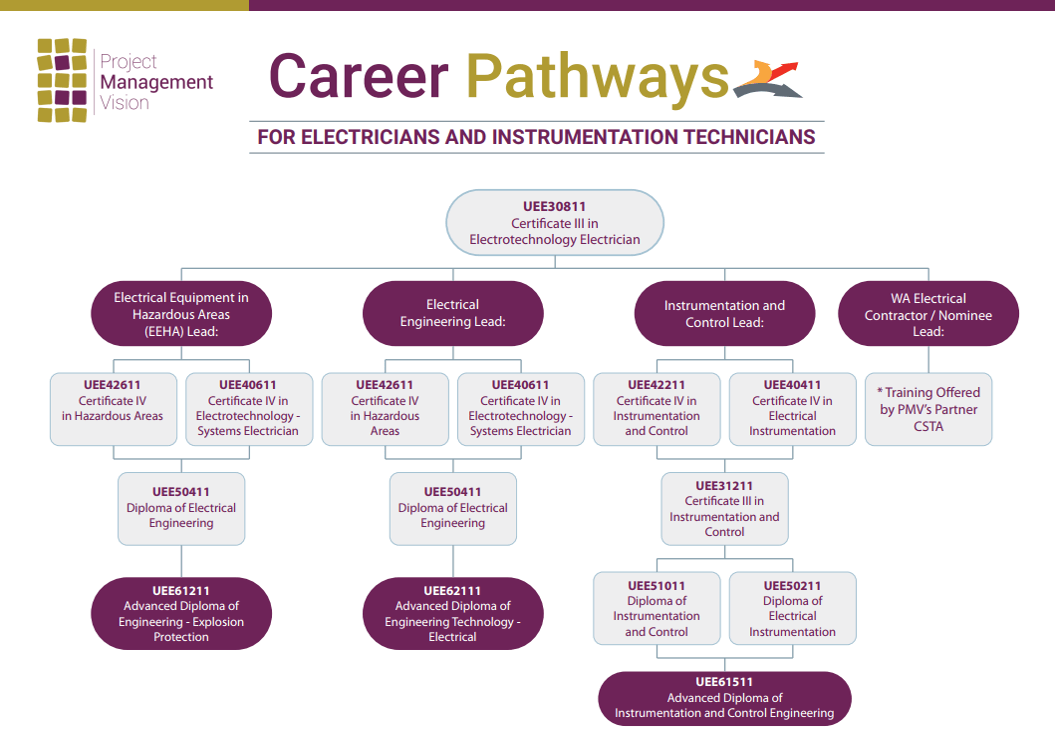

Industries that consist of dangerous areas are currently demanding that electric workers that are specifying or operating in these locations must have a harmful location qualification that considers them qualified. Jobs in these sectors are very rewarding so you need to be prepared. To fulfill this need for the market, nationally recognised training in Certification IV in Harmful area Electrical and EEHA training on the advancement of knowledgeable professionals.

Roar Solutions Things To Know Before You Get This

Tech Skills Australia is a Find Out More Registered Training Company offering you with the most budget-friendly and quickest means in acquiring your credentials - eeha. Our teachers are sector certified and have numerous years of procedure experience. Our courses have assisted thousands of people from company managers to everyday workers in obtaining a strong hold on this not so complex however high risk training

The training additionally consists of recognizing the dangerous locations, sources of surge and the homes of unsafe products together with the obligations and functions of all celebrations, laws, systems, criteria and method codes attached to dangerous areas. We supply instrumentation and harmful location options that remain in compliance to latest AS/NZS and international industry standards.

Report this page